- Jopar

- China Foshan

- 60Days

- 20Sets/Months

Polishing machine is mainly used for polishing and drawing the surface of stainless steel pipe.Polishing pipe.

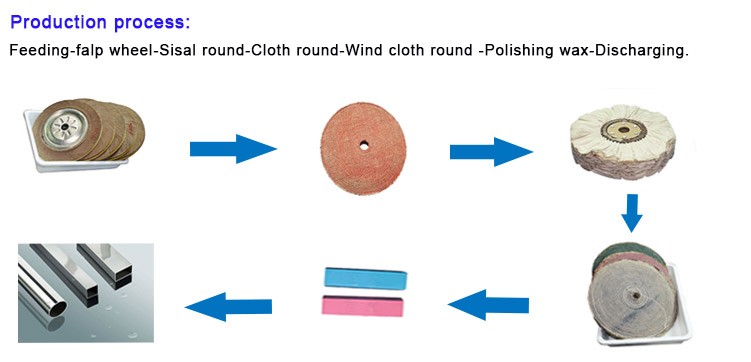

Polishing technology processes:feeding,polishing(flap wheel,sisal round,cloth round,with cloth round)plus polishing

wax,and discharging.The polishing machine is widely used in the decoration industry.

8 Heads Decoration Round Tube Polishing Machine Equipment

TECHNICAL PARAMETERS

Model | Driving Motor | Total Power | Diameter Of Head Spindle | Polishing Range | Speed | (L*W) Dimension |

8 Heads Round Tube Polishing Machine | 4kw*8 | 29.5kw | 36mm | 8-51mm | 0-20 m/min | 5300*1250mm |

10 Heads Round Tube Polishing Machine | 4kw*10 | 45.5kw | 36mm | 12-76mm | 0-20 m/min | 6500*1300mm |

10 Heads Big Tube Round Polishing Machine | 5.5kw*10 | 60.5kw | 36mm | 30-114mm | 0-18 m/min | 7200*1550mm |

10 Heads Industrial Round Tube Polishing Machine | 7.5kw*10 | 82.5kw | 36mm | 89-219mm | 0-15 m/min | 7500*1600mm |

10 Heads Liquid Wax Polishing Machine | 5.5kw*10 | 60.5kw | 36mm | 38-114mm | 0-18 m/min | 7200*1550mm |

1.Description: Round, Square and rectangle tube polishing machine .

2. Application: Mainly used for polishing and drawing the surface of stainless steel pipe with drawing.

3. Continuous polishing process: After feeding, polishing (flap wheel, jute abrasive wheel, cloth wheel, wind cloth wheel), plus polishing wax, discharge and other technics.

4. As the stainless steel polishing machine polishing technology is mature, widely used in decoration.

5. Convenient operation, high quality, reasonable price, consistent with the quality of domestic and international market demands, making high-quality, high brightness of the tube.

Polishing Effect :

Polishing Material:

Packaging & Shipping