- ZP

- China Foshan

- 60Days

- 15Sets/Months

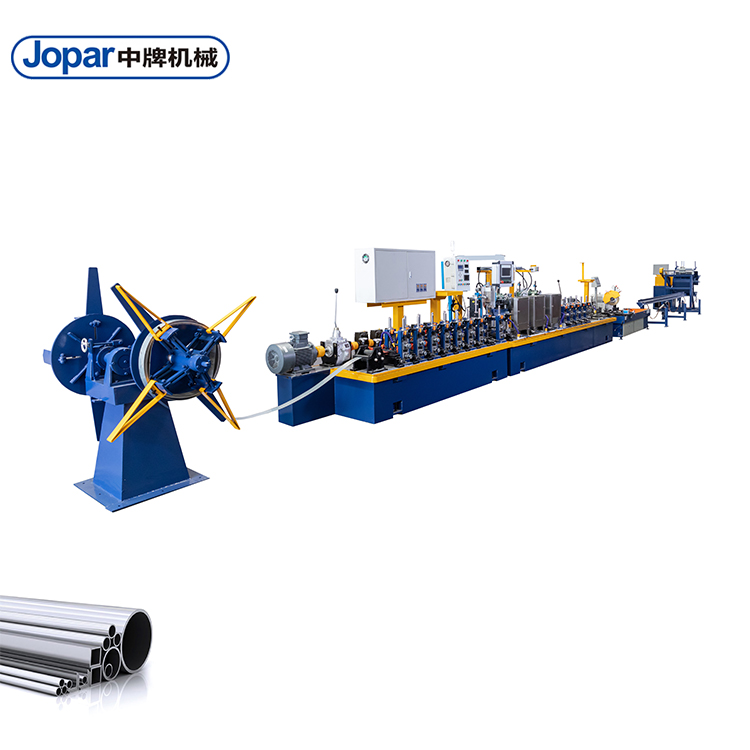

Foshan Jopar Machinery Co.,Ltd mainly manufacturing decorative and industrial high frequency steel tube welding machine.

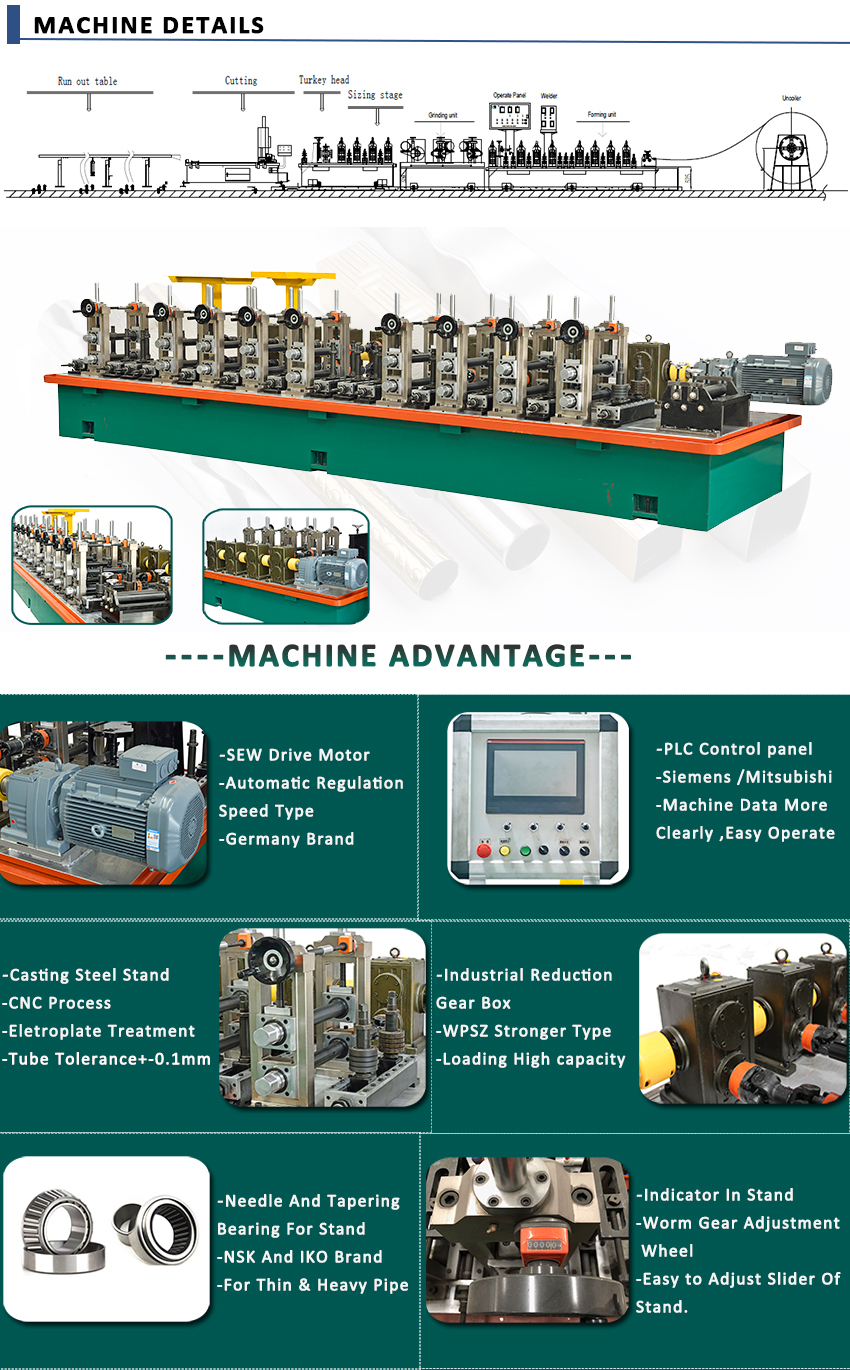

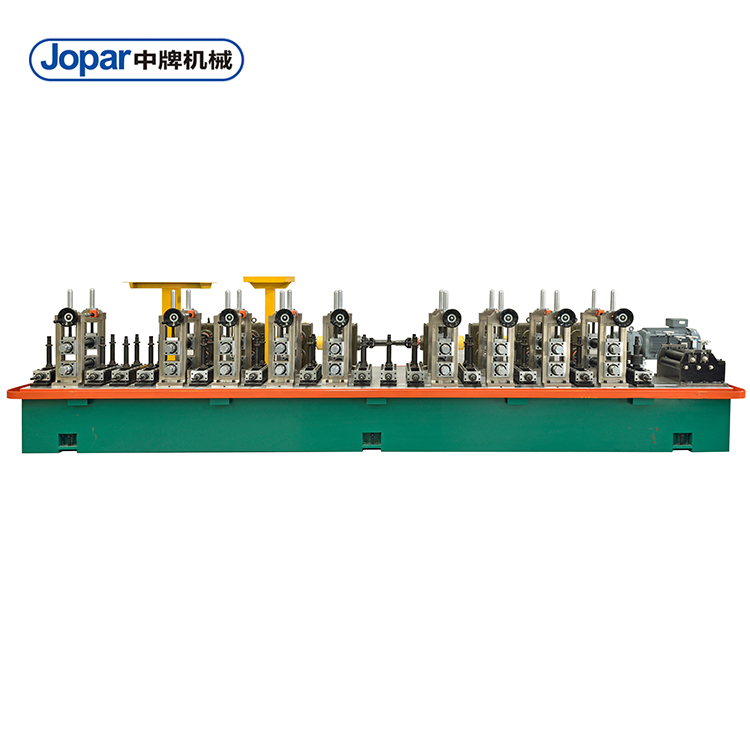

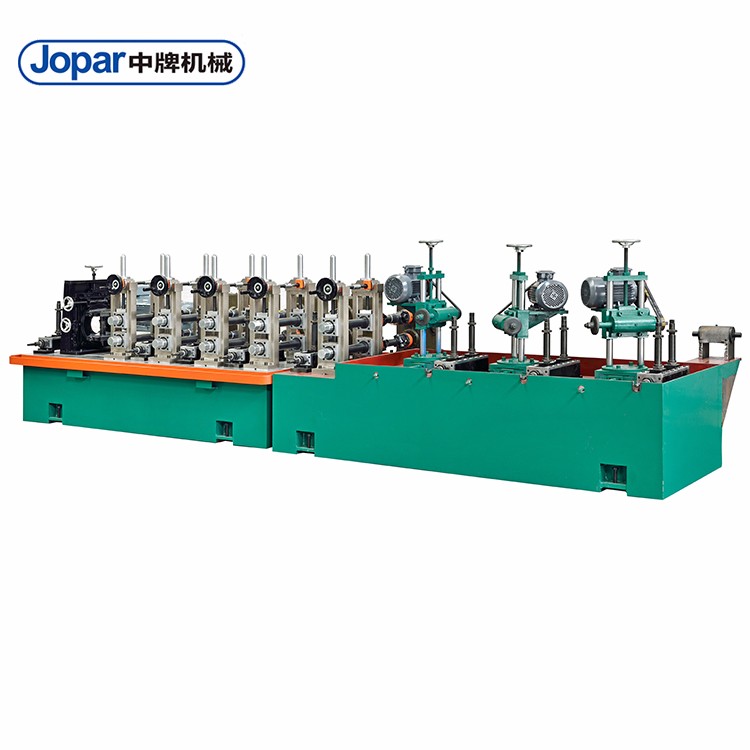

Production process: Uncoiler-- Forming stage--Welding stage--Welded head grinding stage--Sizing stage--Automatic cut of stage--End- product frame

Production capacity:1-10 m/min

Welder type: Ultrasonic Welding machine

Cutting stage: Metal saw cutting stage

Pipe shape : single slot pipe

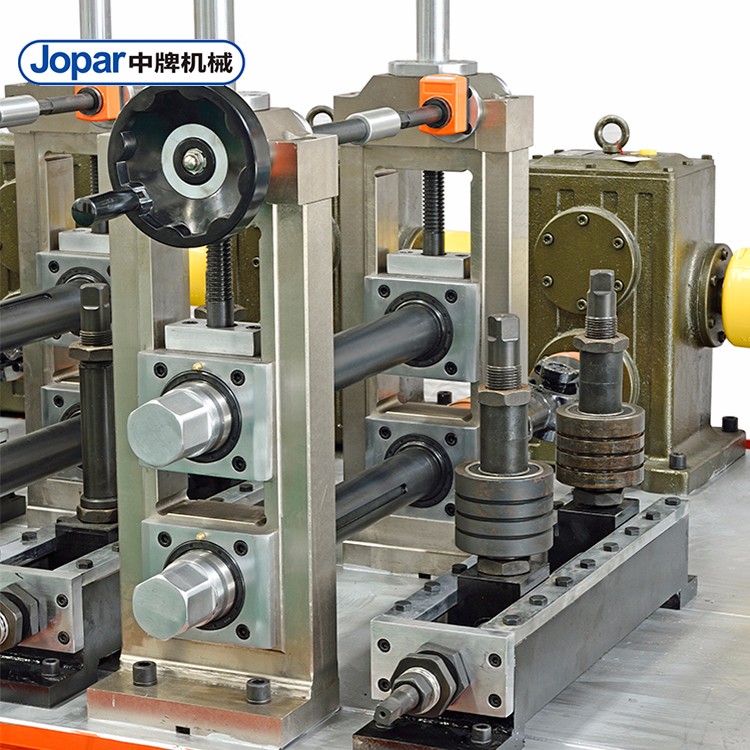

stronger holder with stronger gear box

Material: Our pip making machine can make Stainless steel , Carbon steel , Copper , Iron, MS, GI,Aluminium etc

Application: Mainly used for decoration, products, appliances stainless steel pipe and carbon steel (round tube, square tube, shaped tube) production.

If you are interested, welcome to contact us at any time.

Heat Exchangers Metal Tianium Pipe Making Machine

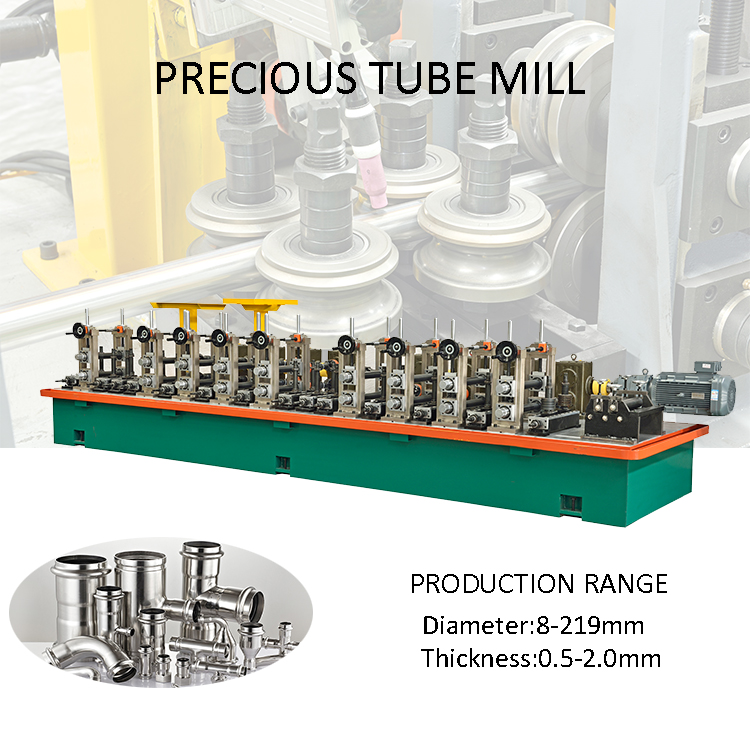

TECHNICAL PARAMETERS

| Model |

Horizontal Shaft Size |

Vertical Shaft Size |

Out Diameter Range |

Thickness |

Drive Motor |

Dimension |

| ZP-P40 | 40mm | 25mm | 8-51mm | 0.5-2.0mm | 7.5kw+7.5kw | 21m*1.3m |

| ZP-P50 | 50mm | 30mm | 25-76mm | 0.5-3.0mm | 11kw+11kw | 23m*1.5m |

| ZP-P60 | 60mm | 40mm | 50-114mm | 0.6-3.5mm | 15kw+15kw | 25m*1.6m |

| ZP-P80 | 80mm | 50mm | 89-168mm | 1.0-4.5mm | 18.5kw+18.5kw | 32m*2.5m |

| ZP-P100 | 100mm | 60mm | 114-219mm | 1.0-5.0mm | 22kw+22kw | 43m*3.0m |

|

OFFERING THE PROFESSIONAL WELDED TUBE SOLUTIONS |

||||||

PRODUCT ADVANTAGES

Professional material:its appearance is made up of superior stainless steel

engineering material,having the advantage of durability.

Precise structure:it uses high-tech the design of elaborate motor structure,

having the advantage of stable performance,energy conservation and envizronment protection.

Easy operation:its humanizronment design of operating system makes

it have the advantage of learn ability and easy operation.

Quality assurance:the products have passed the ISO9001 international

quality management system certification,having the advantage of high

quality and prestige.