- Jopar

- China

- 90Days

- 15Sets/Months

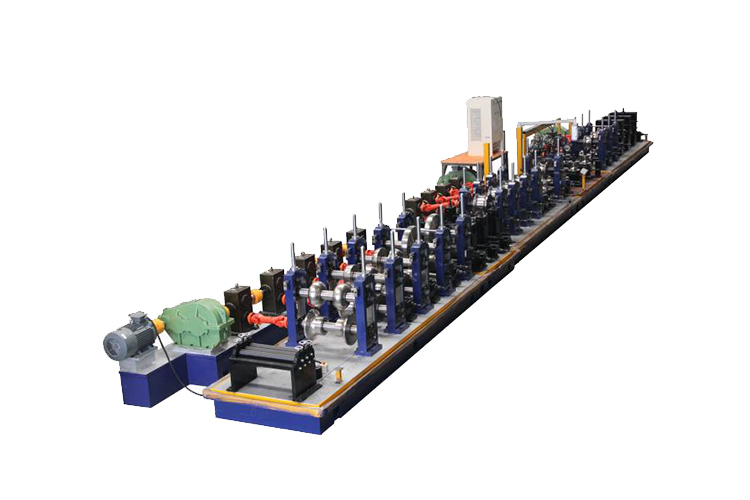

Large diameter tube mill,The layout of this machine is 5413,This machine have adopted separate machine bases design, one side is installed the motor, gearbox etc. Another side is installed stands and rollers. This design help us to dispatch the machine to abroad and customer make installation conveniently.

This machine have adopted separate machine bases design, one side is installed the motor, gearbox etc. Another side is installed stands and rollers. This design help us to dispatch the machine to abroad and customer make installation conveniently.

Here is matched with a movable PLC control panel. You can watch and set the technical data of machine easily. And this PLC panel is connected with a Independent electric cabinet, all of MCBs and inverters are in this cabinet., a pipe making machine have 6 components: uncoiler, forming and welding stage, grinding stage, sizing stage, cutting stage and run out table.

TECHNICAL PARAMETERS

| Model | Horizontal Shaft Size | Vertical Shaft Size | Out Diameter Range | Thickness | Drive Motor | Dimension |

| ZP-S100 | 100mm | 50 | 127-219mm | 2.0-6.0mm | 30(kw)*2 | 40m*2.6m |

| ZP-S110 | 110mm | 70 | 219-325mm | 3.0-8.0mm | 45(kw)*2 | 5.0m*4.0m |

| ZP-S120 | 120mm | 75 | 325-426mm | 4.0-10.0mm | 55(kw)*2 | 53m*4.5m |

| ZP-S130 | 130mm | 80 | 377-530mm | 5.0-12.0mm | 75(kw)*2 | 58m*4.5m |

| ZP-S150 | 150mm | 85 | 426-630mm | 5.0-12.0mm | 95(kw)*2 | 61m*5.5m |

| ZP-S160 | 160mm | 90 | 426-630mm | 6.0-14.0mm | 110(kw)*2 | 65m*6.0m |