- ZP

- China Foshan

- 45Days

- 20Sets/Months

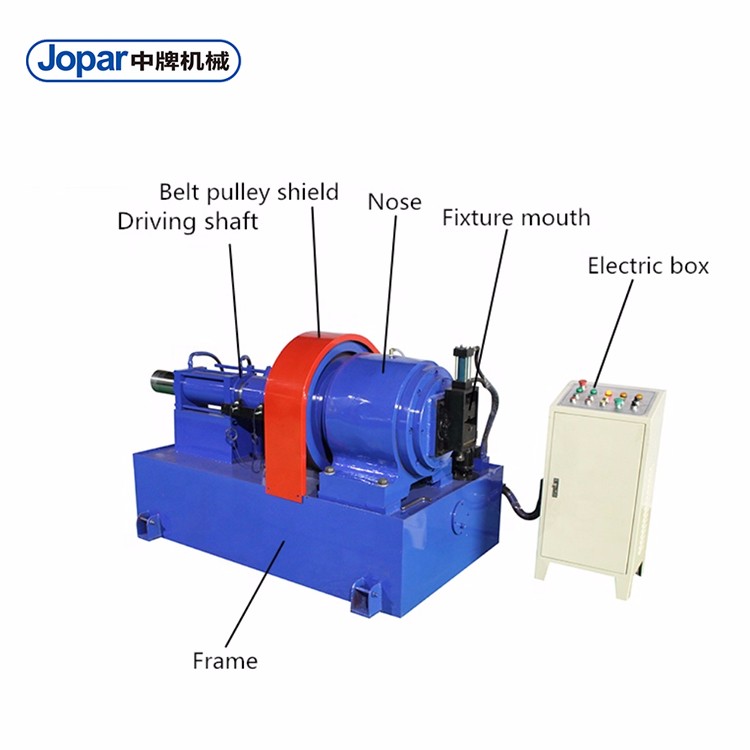

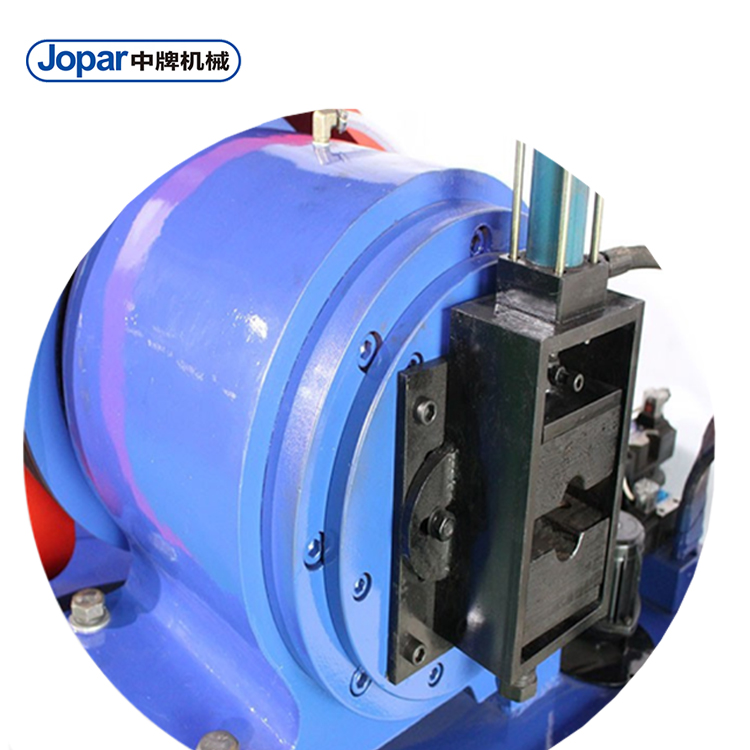

Stainless steel embossing machine,also known as stainless steel flower pipe froming machine,is mainly used for embossing stainless steel pipe,iron pipe,aluminum pipe and so on.The embossing machine can variey of flower

shapes,such as flat flower,round floewr,craft flower,bulk flower,egg flower,etc.

Workbale diameter of pipe range from (6-114)mm,pipe Thickness from (0.2-3.0)mm,With good processing quality,

lower cost and high efficiency,the embossing machine is an ideal choice for clients to process various kinds of flower

pipes.

Stainless Steel Pipe Tube Flower Machine

TECHNICAL PARAMETERS

| Model | EM25 | EM50 | EM76 | EM114 |

| Mould Dimension(mm) | 35*300*55 | 50*300*75 | 70*400*60 | 90*650*70 |

Process Scope (mm) | 12-25 | 16-51 | 25-76 | 38-114 |

| Process Thickness(mm) | 0.2-1.5 | 0.2-2.0 | 0.4-7.5 | 0.7-3.0 |

Process Lenth (mm) | 290 | 290 | 360 | 600 |

Time Of Foring (Second) | 3-12 | 3-20 | 8-30 | 10-40 |

| Main Motor Power(kw) | 3 | 4 | 7.5 | 11 |

| Rotation Rate Of Axis(Rpm) | 300 | 200 | 200 | 200 |

| Gross Weight(kg) | 1500 | 2000 | 3000 | 5000 |

1. Name: Embossing machine

2. Advantage: Can make many flower shapes for the customers

3. Pipe material :Process ss, iron, aluminium tube.

4. Certificate: ISO9001:2008

5. Processing: stainless steel pipe, iron pipe, aluminium pipe.

6. Flower shape: flat flower, round flower, craft flower, bulk flower, egg, flower and others.

7.Advantage:The embosing technique has good processing quality, low cost and high efficiency characteristics.

Features:

1.Stainless steel embossing machine, also flowers tube molding machine.

2.Use of foreign advanced technology , stainless steel , Iron ,Aluminum tube for a variety of processing

3.Flat flowers, Round flowers ,Big flowers. Craft flowers , Eggsand flowers,Etc

4.Machinable the scope of the diameter (12-114mm), Thickness (0.3-2.5mm)

The machine features :

1.The machine has the fastest processing efficiency ,Speed 2Sforming, Faster than the counterparts.

2.The machine processing wall thickness (0.184.0mm), the same as the products processing wall thickness tube (0.35-1.2mm).

3.The noise of the machine is low.